Knowledge

Trainees know …

- the tools and machines used on the building site for plastering and cladding straw bale walls. They know specific requirements for finishes on a straw bale building site,

- the possible dangers, safe working practices, accident prevention regulations and security data sheets,

- about the specifics of plaster/render materials, their advantages and disadvantages, how to make proper mixtures and how to work with,

- about the specifics of the cladding materials and fastenings, their advantages and disadvantages, how to make the right connections and dimensions,

- the basics of weather proofing, wind and air tightness, fire protection and vapour barriers for rendering/plastering finishes of straw bale buildings,

- the basics of weather proofing, wind- and rain tightness, rainwater drainage, protecting splashwater areas, making barriers and supporting constructions for cladding systems,

- good detailing for plastering/rendering/cladding straw bale walls,

- why and how to make rendering/plaster samples to choose the right mixture,

- the different surface structures and treatments and their advantages and disadvantages, [Level 4]

- how to prepare the substrate for the plaster,

- the consistence of plaster/render and how and when to use meshes,

- how to prepare the straw bale wall for the cladding system and how to install the different systems.

Skills

Trainees can …

- handle tools and machines which are used for different rendering and cladding systems,

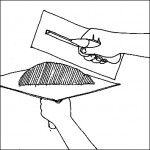

- prepare the substrate,

- prepare the plaster/render mixture,

- execute different plaster systems,

- prepare the wall and install the supporting constructions for cladding,

- prepare and install the cladding systems,

- estimate the dangers of handling with these materials and can minimise risk,

- execute proper airtightness, wind- and rain-proof details and take care for good rainwater drainage,

- organize and do the work on time, [Level 4]

- calculate the rendering/plastering and cladding quantities, [Level 4]

- apply different surface structures, treatments and protecting paint coats.

Competence

Trainees can …

- be aware of health and safety in relation to other workers, building site, machinery, equipment, PPE (personal protective equipment) and of issues specific to working with earth, lime and cladding systems,

- organize the building site at all stages, [Level 4]

- explain different examples of rendering and cladding, making reference to advantages and disadvantages of each and can announce concerns. [Level 4]

Materials/Documents:

U5 Learning Outcome – Level 3 | ECVET credit points: 25

U5 Learning Outcome – Level 4 | ECVET credit points: 20

U5 Session 1: Direct Plaster Theory 4 hours

U5 Session 2: Direct Plaster Practice – Wall Preparation 1 day (incl. practice)

U5 Session 3: Direct Plaster Practice – Clay Mix Preparation 1 day (incl. practice)

U5 Session 4: Direct Plaster Practice – Clay Base Coat 1 day (incl. practice)

U5 Session 5: Direct Plaster Practice – Clay Top Coat 1 day (incl. practice)

U5 Session 6: Direct Plaster Practice – Lime Mix Preparation 1 day (incl. practice)

U5 Session 7: Direct Plaster Practice – Lime Base Coat 1 day (incl. practice)

U5 Session 8: Direct Plaster Practice – Lime Top Coat 1 day (incl. practice)

U5 Session 9: Cladding Theory 2 hours

U5 Session 10: Cladding Practice 1 day

Handbook U5:

STEP U5-Handbook EN – Finishes (Clay plasters & Lime renders)

Links: U5 all sessions