Objectives

Trainees are …

- able to organize building site, materials and tools for plaster/render

- aware of health and safety in relation to other workers, building site, machinery, equipment, PPE (personal protective equipment) and of issues specific to working with lime

- able to explain the structure of a lime plaster/render with its several layers

- able to apply the 1st base coat of a multilayer plaster/render

- able to apply the base “filling layers” to make the wall even

- able to apply a reinforcement mesh

Method:

- practical exercises at a workshop or building site together with rlevant theory

Theory:

- how and why to create a 1st layer to bond the plaster/render into the straw

- the structure and composition of lime multilayer plaster/render with their different thickness

- drying/carbonating timings of the different layers and tending (control of humidity, exposure, ventilation, etc.) procedures to ensure drying/carbonating

- connection between layers: remove sinter layer, texturize and wet the surface

- the protection of a drying render from weather conditions

- the need of having humidity on the wall during drying period

Practice/Task:

- Exercises:

- apply a lime slip by hand or using a mechanical spray

- apply base layers of lime with or without fibres to achieve an even wall

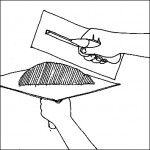

- reinforce by applying mesh

- check the thickness to guarantee bracing function as load bearing material

- check good execution to guarantee a minimum thickness for fire protection, air tightness, water proof, acoustic performance and rodent and insect protection

Materials/Documents: U5 S7 – Session Plan

Training Time: 1 day